To ask such a narrow question, we first must visit what injection molding is when compared to CNC.

These two popular production methods are helpful to many industries, assisting in part fabrication for medical, autobody, engineering, and so much more. Though they can create similar parts, it’s safe to say that injection molding and CNC processes are entirely different from one another. The method you should rely on will ultimately depend on what you’re trying to achieve with your specific project and end goal.

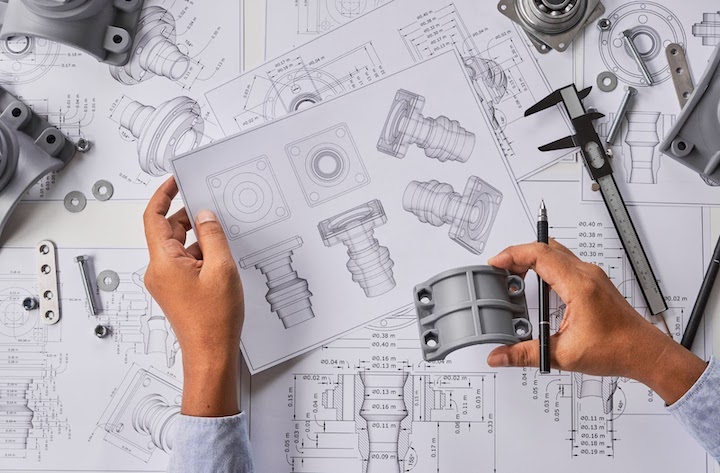

What is CNC fabrication?

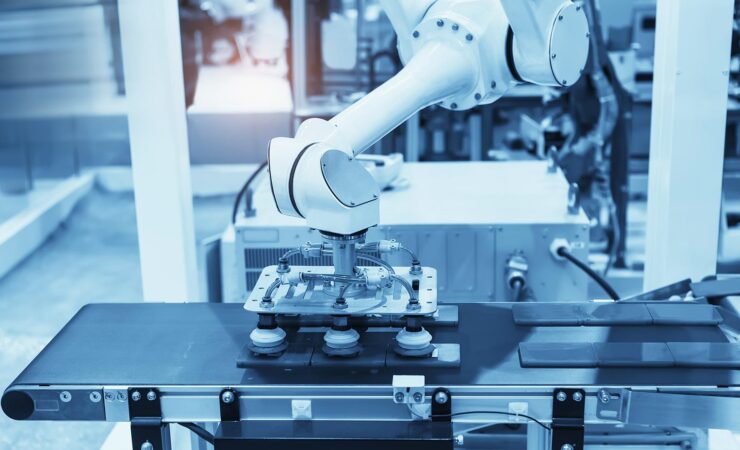

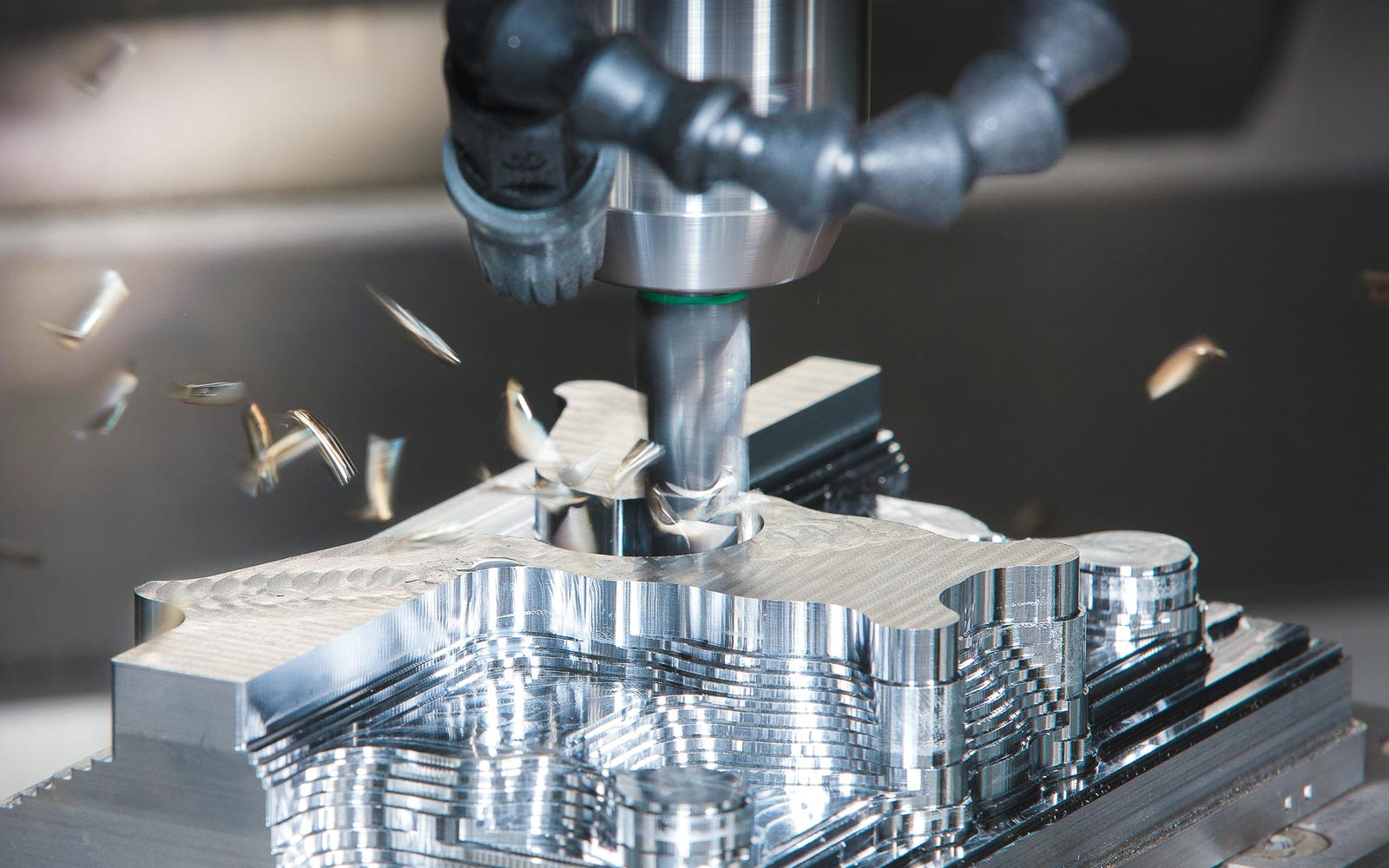

In short, CNC stands for Computer Numerical Control. This way of manufacturing is computer-controlled through a combination of CAD file implementation and a rotating lathe. A physical person is instructed to program the CAD file into the computer, then the rotating lathe reads the file and follows the instructions to cut away at the provided material, producing a pristine end product.

Truth be told, CNC fabrication is very similar to 3D printing. The only significant difference is that 3D printing operates through an add-on process whereas CNC cuts away material that’s already in existence.

What is CNC used for?

CNC can create a range of different products, including but not limited to:

- Medical implants

- Electrical parts

- Prototyping

- Plastic injection molds

- Business signs

- Shipping logistics

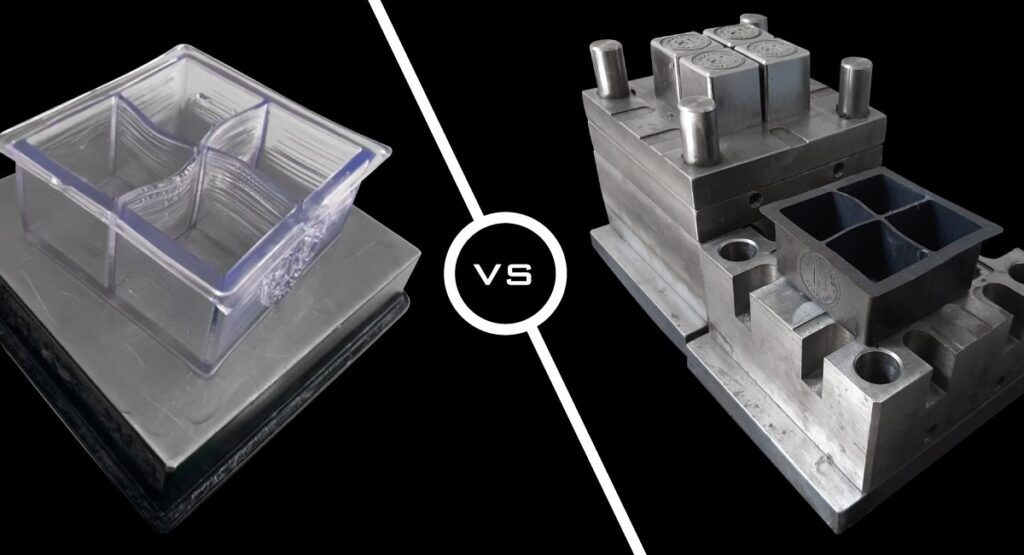

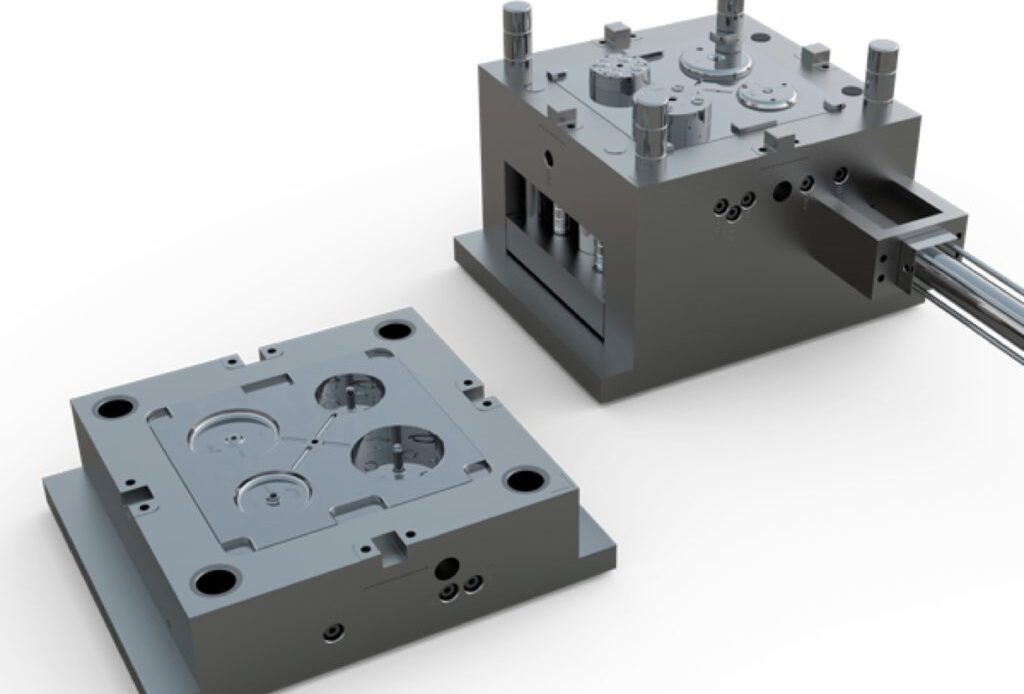

What is Injection Molding?

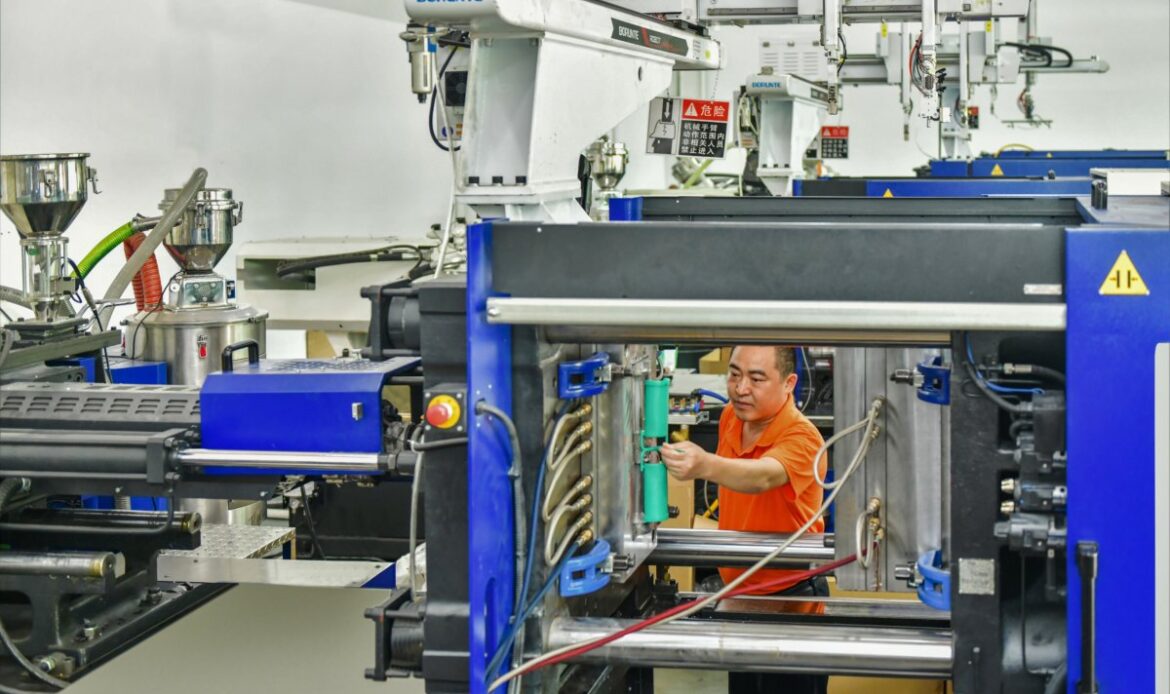

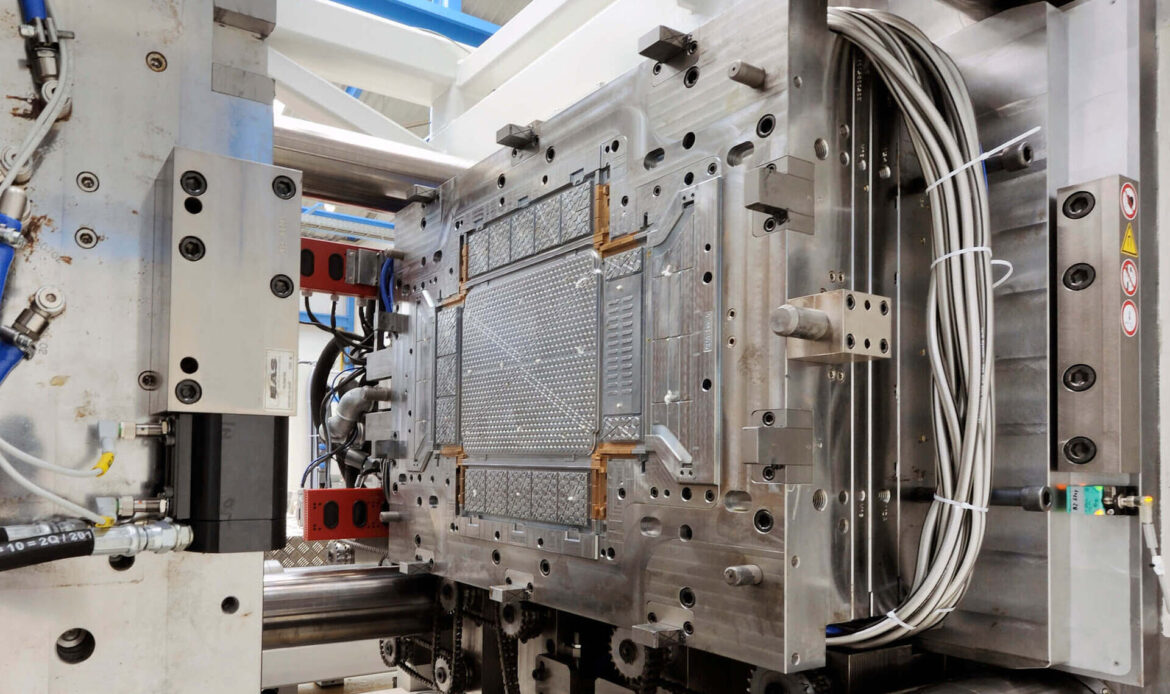

Injection molding methods focus on making parts through a more complex process. First, the plastic is melted inside the machine’s barrel. Then, the melted plastic travels through a tube and into the carefully designed mold. Once filled, the plastic hardens through a temperature regulated process and is cooled before the machine reopens the mold for ejection. Once the product is made, another is immediately put into production.

Molding is quite opposite when compared to that of CNC fabrication, as it involves filling an empty mold. CNC simply cuts away at existing material and molding creates something from small particles.

What is Injection Molding used for?

Injection molding can create a range of different products, including but not limited to:

- Locks

- Feeding troughs

- Plastic beverage caps

- Medical testing kits

- Electronic components

Which process is more cost efficient?

Injection molding is a true investment, and one that shouldn’t be thought of lightly. Designing and producing a mold is not an overnight process; it takes hard work, dedication, and a good chunk of money to produce the part you and your company want to sell. The overall cost to break even from the investment will depend on the product’s complexity and size, small or large. And, you’ll want to consider whether or not the item can/should be mass produced to make a real profit.

On the other hand, CNC fabrication only requires the maker to have a CAD file and the allotted amount of material needed to complete the process. You can do one item or dozens of items. But just because CNC is more cost efficient doesn’t mean you should throw the idea of injection molding out the window, especially if you’re looking to streamline one product into a mass production lineup.

What about materials?

Injection molding has a narrow material playing field, as its best use is through plastics and resins. On the other hand, CNC fabrication can be more versatile, making use of materials like metal, wood, plastics, and wax. Why is this? Some say it is because a CNC machine has a very high heat tolerance. That doesn’t minimize risk when it comes to product warping, though, which is why injection molding is a much better option when it comes to manufacturing products out of rubber and plastic.