The phrase “plastic injection molding” doesn’t necessarily explain itself. All we can really gather from the titled question is that there is a process that needs to be explained, and it may or may not have something to do with molding and fabricating equipment out of on-hand supplies. So let’s get into the details with this article.

What is Injection Molding?

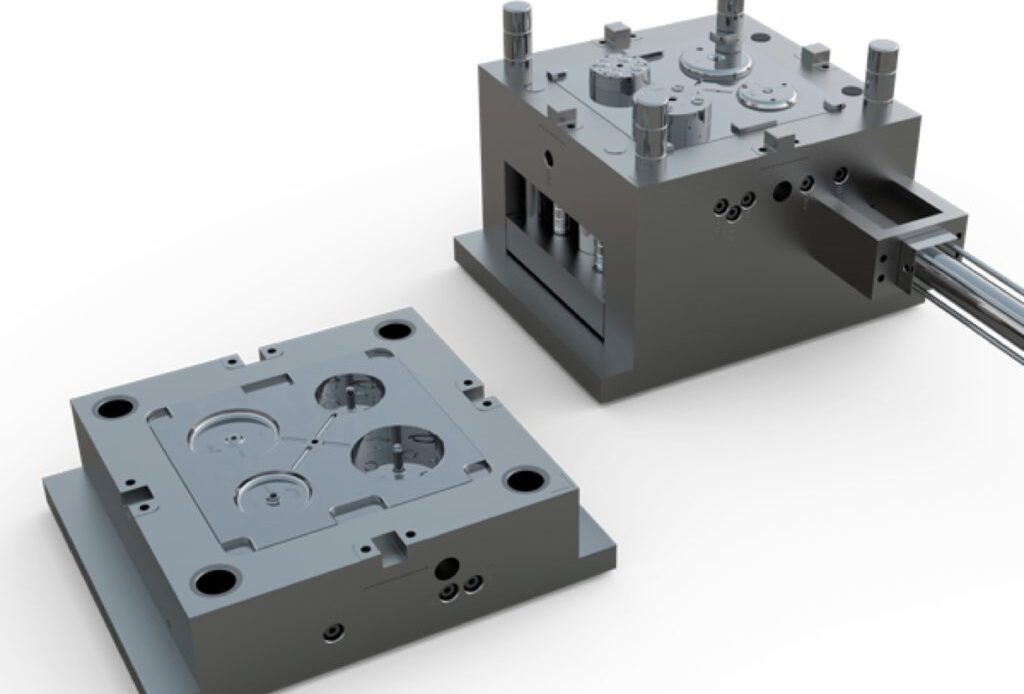

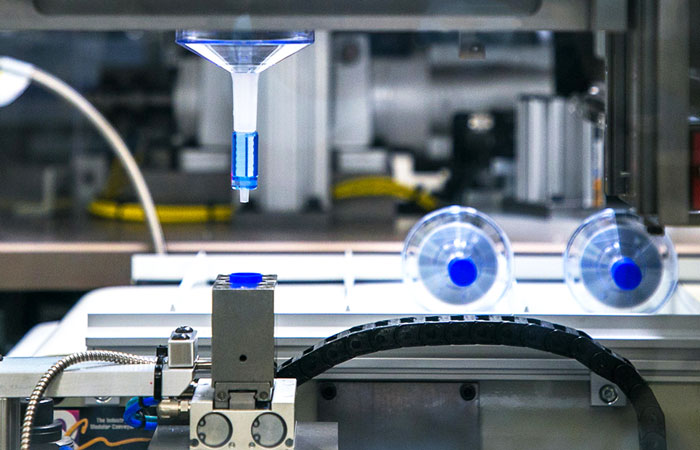

Injection molding is a type of manufacturing process that companies use to produce parts in bulk. Oftentimes, a business will use this technique if they’re replicating the same part over and over again, thousands to millions of times.

Why Would You Want to Use Injection Molding?

The #1 reason to adopt the methods that injection molding employs is to ready your workers for mass production. Scaling production down to minimalistic processes makes it easy to hire inexperienced employees and train them to follow directions in an assembly line setup.

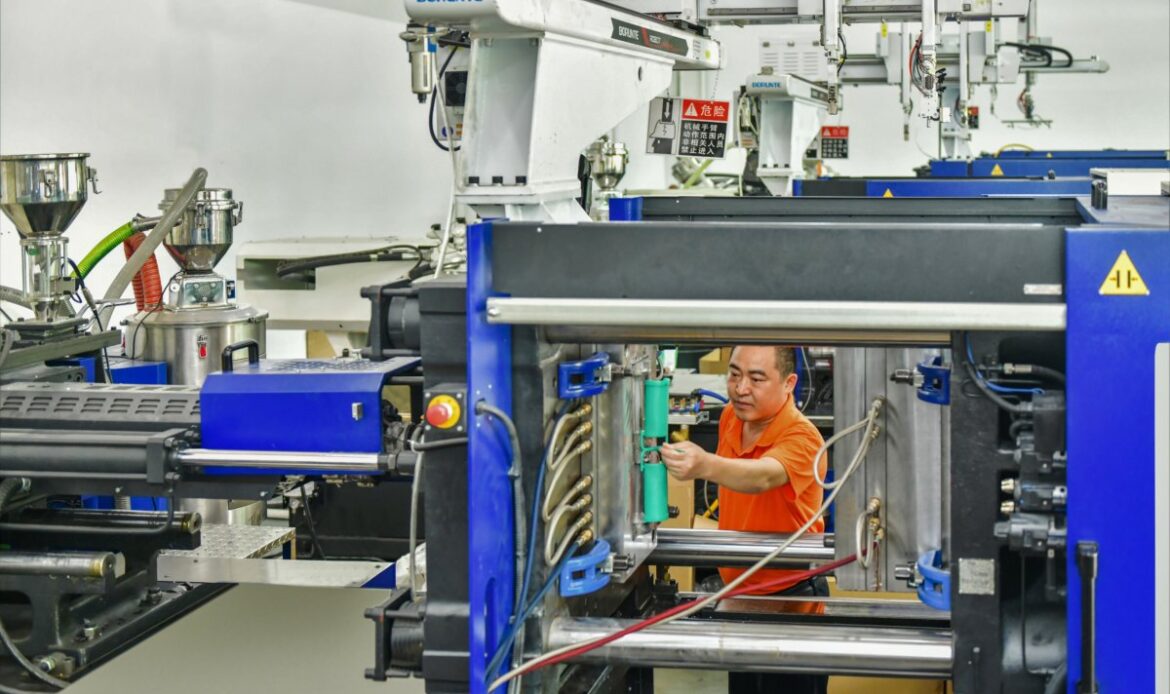

The initial costs of adopting injection molding processes may be costly, but once the investment has been paid off, the price to continuously manufacture parts is extremely low. Basically, the more parts produced, the cheaper the process is.

Outside of keeping costs down, injection molding can do so much more. Check out some advantages below.

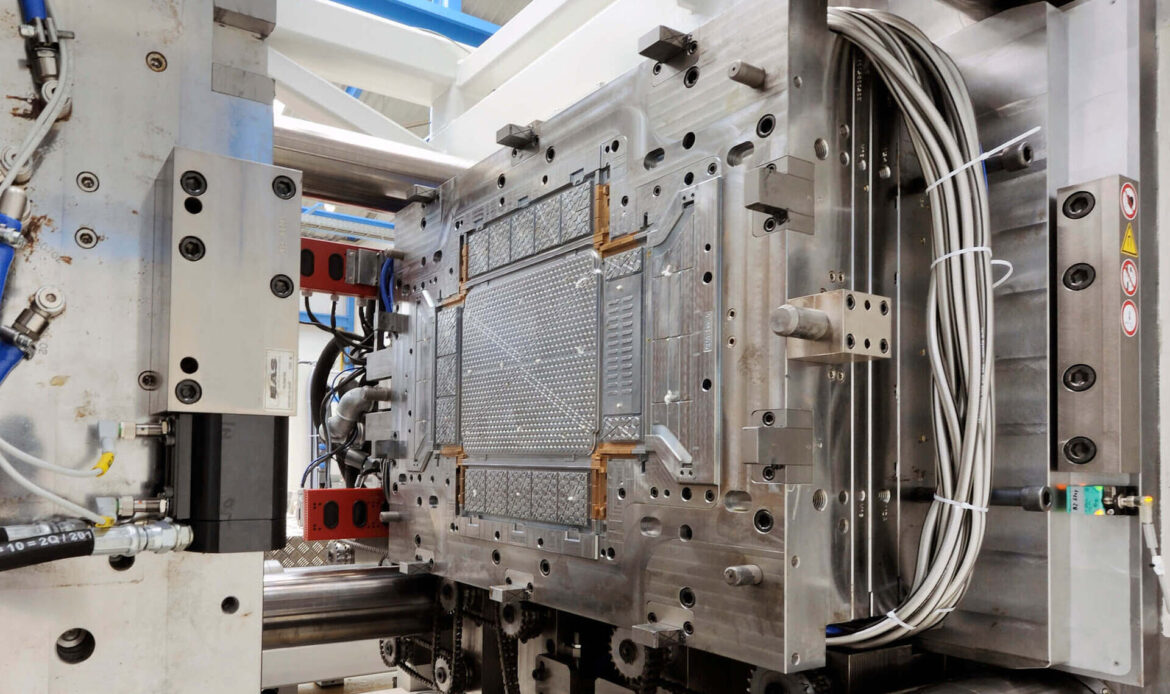

Low Scrap Rates

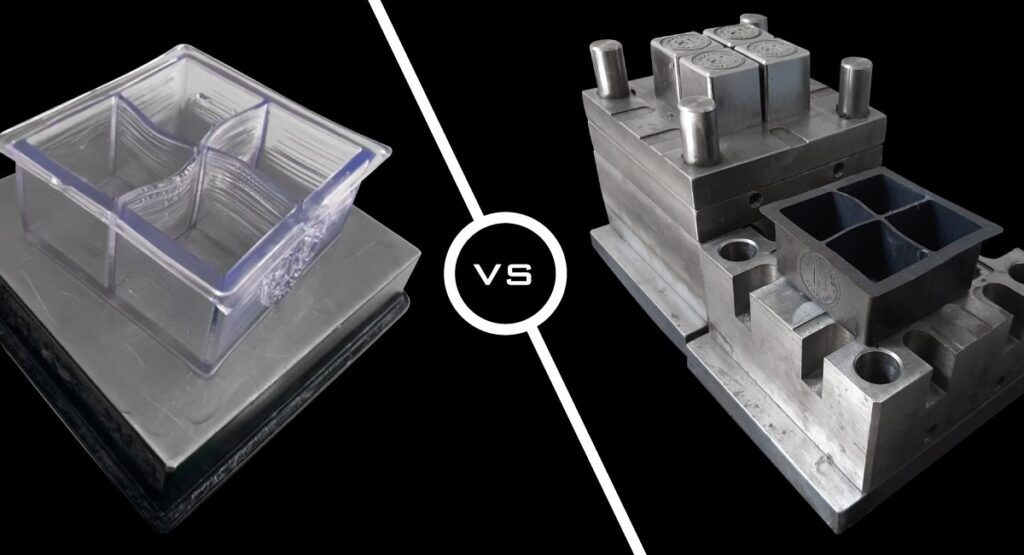

Scrapping materials is really not what any company wants to do. Luckily, injection molding produces relatively no scraps, as all the material is put to use. In other manufacturing processes like CNC machining, the opposite is true. You see, CNC cuts away a large amount of the original plastic block or sheet, getting rid of usable material while cutting through.

That’s not to say that injection molding is the most preservative method, because it’s not. 3D printing has just about the lowest scrap rate to date, but at least injection molding is efficient and a step in the right direction.

Repeating Consistency

Another bonus of working with the injection molding process is that it can be repeated to no end. The second part will be identical to the first, the third will be identical to the second, and so on.

Why should you be proud of repeating consistency? Because when you’re trying to build a brand, you can safely say that your process is reliable every step of the way, even in high production environments. Whatever one person orders today will be the same in a year from now, unless you physically change your product to be something else.

One Thing to Consider: Finances

Though injection molding has many benefits, it’s still a good idea to cover all of the basics before jumping right in. Like, financial considerations.

In the long run, injection molding will save you money if you’re producing a product at a very high volume. If you’re only producing a few hundred items a year, weighing the pros and cons of other manufacturing processes may be in your best interest.

Our best advice would be to sit down and thoroughly determine the number of parts you expect you’ll have to produce to break even with an injection molding investment. Remember, you’ll have to design the part, test the part, produce it, visualize its assembly, market it to the public, and distribute it. All of these factors will determine a narrower profit and loss report for your analysis.

If you think that injection molding will be worth the cost after review, you can move on to the next step in the process.

Where Can You Go To Get Information On Plastic Injection Molding Processes?

The answer to that question is easy, Advance Plastics.

Advance Plastics sets a quality-assured high bar when it comes to custom injection molding products. The cost effective initiative proposed will provide every customer with the opportunity to deliver efficient products on time, every time. Great results guaranteed.

With Advance Plastics on your side, you’ll be a leader in the industry from beginning to end, designer concept to product completion. Great quality, customer service engagement, and the best service around. Your satisfaction is priority, 100% of the time.